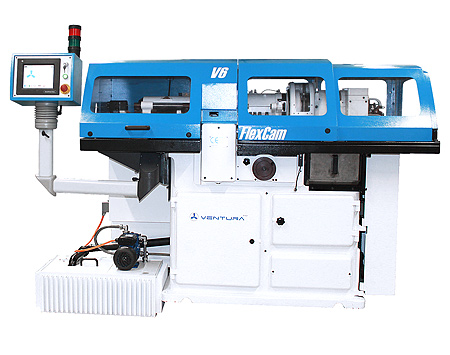

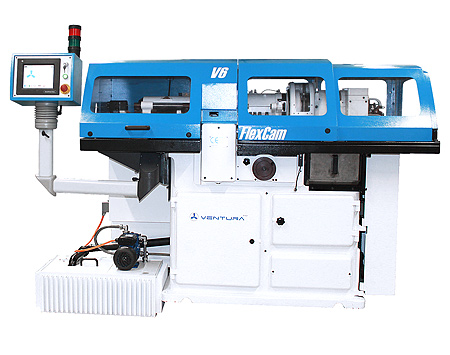

Ventura V6 FlexCam

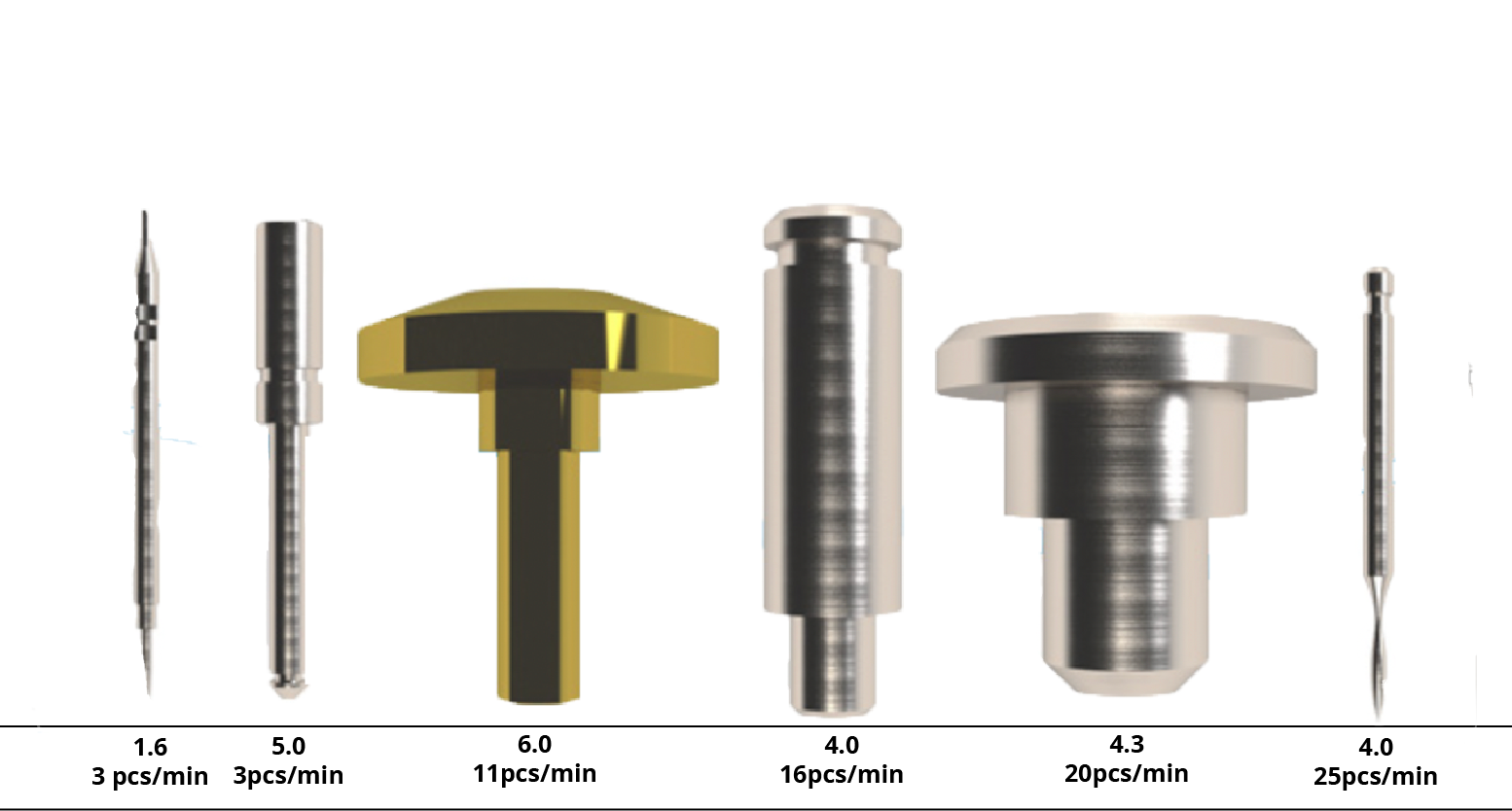

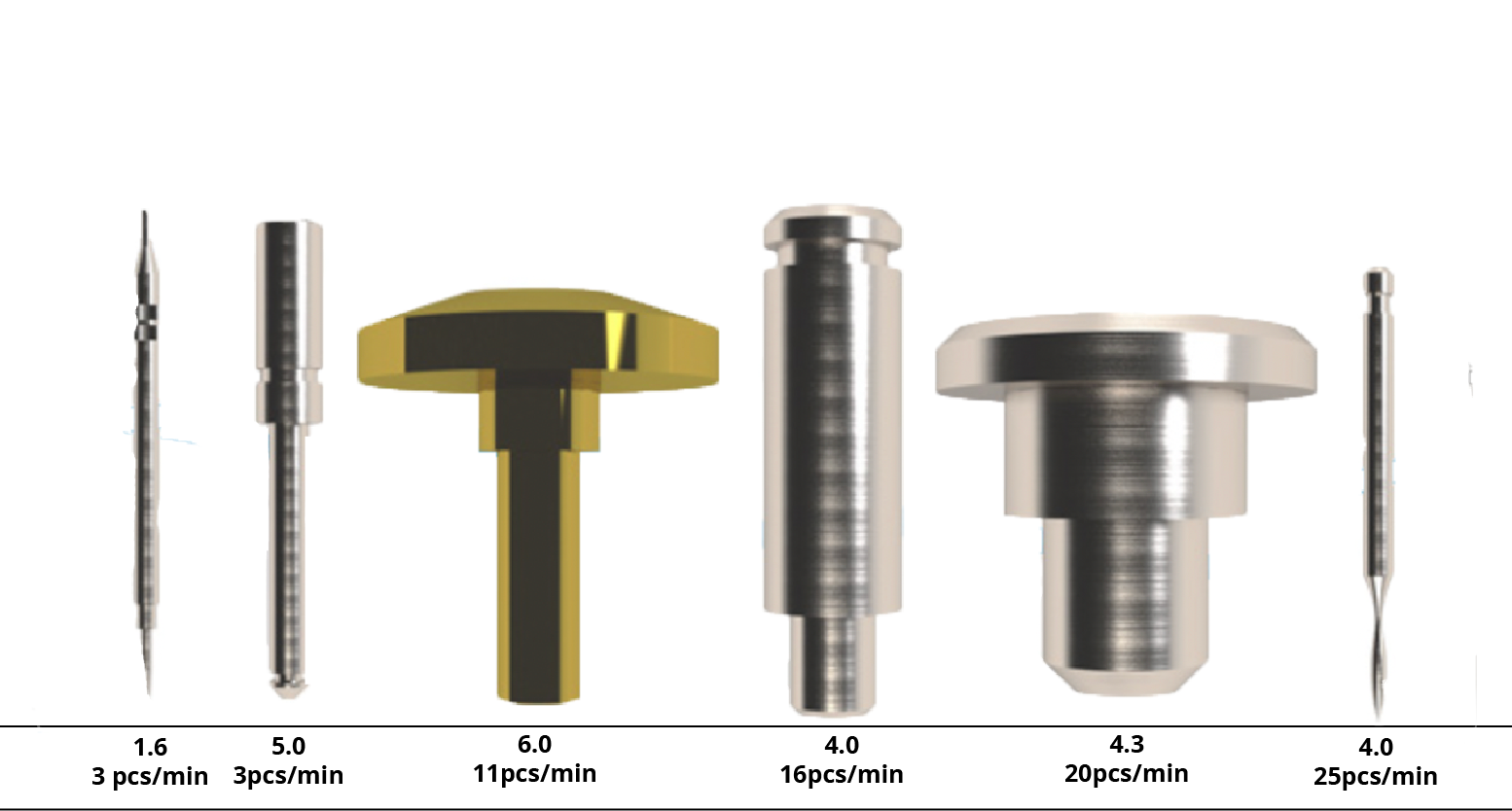

The Ventura V6 FlexCam is the fastest solution for the economical and precise production of medium and large series of parts with a diameter of up to 6.35 mm, from coil stock.

The VENTURA V6 is equipped with a counter-collet and its support, enabling cutting without cut-off burrs. This configuration makes it possible to mass produce parts without threading or drilling such as: axes, pinions, pins, needles, etc…

The distance between bush and collet is adjustable. Collet tightening and loosening are controlled by adjustable segments attached to the cam shaft. The lubricant is delivered to the part which is being machined by 6 converging jets. Part of the flow is detoured to the collet where it ensures ejection of the part and cleansing of the collet.

The safety stop works when the material has run out. This type of machine is suitable for turning parts which require no other operations than turning.

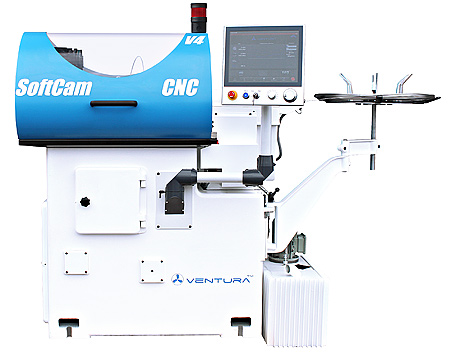

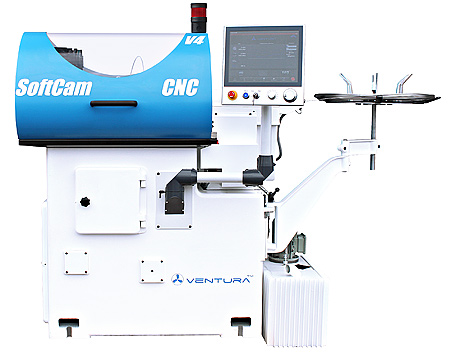

The Ventura SoftCam system allows for individual optimization of operational parameters. The possibility of programming the cam shaft speed per segment increases the performance of the cam machines. E.g. it is possible to slow the feed during sectioning and to increase it while turning. Thanks to this technology, overall cycle time is no longer determined by the slowest process. In addition, spindle and straightener speeds can be adjusted throughout the entire program (no more changing pulleys; plus significant improvement in quality of the parts produced, both as to tolerances and surface finish).

- Simple parts

- Coil stock

- Material diameter up to 6.3 mm (maximum in mild steel)

- Very short production cycles

- Three independent tools turning operations

- Non-stop 24-h production

- Easy start-up

- Easy production process adaptation

- Optimized run cycles thanks to the FlexCam system, resulting in greater precision and longer tool life.

- Economical and efficient production of simple parts with short production cycles.

- Reduction of materials cost via significant reduction of offcuts.

- Machined parts without cut-off burrs, thus avoiding costly reworking.

- Since the part is better anchored, feed rates for plunge operations or cutting can be higher.

- Reduced manufacturing costs due to space-saving design of the coil machines (compact design).

- Reduced labor since machines are fed (material loaded by coil) at longer intervals, true 24/7 continuous work. The operator can use the time freed up to run more machinery.

- Production halts due to loading are less frequent.

Ventura V6 FlexCam

The Ventura V6 FlexCam is the fastest solution for the economical and precise production of medium and large series of parts with a diameter of up to 6.35 mm, from coil stock.

The VENTURA V6 is equipped with a counter-collet and its support, enabling cutting without cut-off burrs. This configuration makes it possible to mass produce parts without threading or drilling such as: axes, pinions, pins, needles, etc…

The distance between bush and collet is adjustable. Collet tightening and loosening are controlled by adjustable segments attached to the cam shaft. The lubricant is delivered to the part which is being machined by 6 converging jets. Part of the flow is detoured to the collet where it ensures ejection of the part and cleansing of the collet.

The safety stop works when the material has run out. This type of machine is suitable for turning parts which require no other operations than turning.

The Ventura SoftCam system allows for individual optimization of operational parameters. The possibility of programming the cam shaft speed per segment increases the performance of the cam machines. E.g. it is possible to slow the feed during sectioning and to increase it while turning. Thanks to this technology, overall cycle time is no longer determined by the slowest process. In addition, spindle and straightener speeds can be adjusted throughout the entire program (no more changing pulleys; plus significant improvement in quality of the parts produced, both as to tolerances and surface finish).

- Simple parts

- Coil stock

- Material diameter up to 6.3 mm (maximum in mild steel)

- Very short production cycles

- Three independent tools turning operations

- Non-stop 24-h production

- Easy start-up

- Easy production process adaptation

- Optimized run cycles thanks to the FlexCam system, resulting in greater precision and longer tool life.

- Economical and efficient production of simple parts with short production cycles.

- Reduction of materials cost via significant reduction of offcuts.

- Machined parts without cut-off burrs, thus avoiding costly reworking.

- Since the part is better anchored, feed rates for plunge operations or cutting can be higher.

- Reduced manufacturing costs due to space-saving design of the coil machines (compact design).

- Reduced labor since machines are fed (material loaded by coil) at longer intervals, true 24/7 continuous work. The operator can use the time freed up to run more machinery.

- Production halts due to loading are less frequent.

Get in touch with us.

If you have any questions, or would like a quote please call 603-524-0082, or leave us a message by filling out our contact form. You can also send us and email if you prefer to info@swissettool.com.