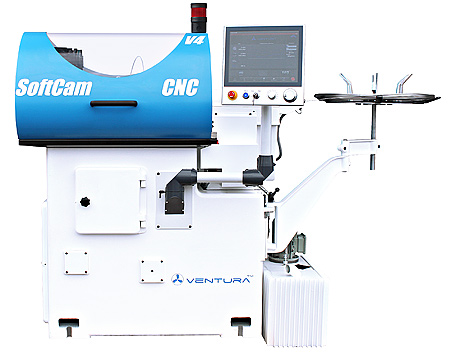

Ventura V4-V5 SoftCam

Thanks to the revolutionary and innovative development of the Virtual Cam, the V4/V5 SoftCam is the only CNC machine on the market that can reach the same cycle times as a cam machine.

This machine is the evolution of the V2 SoftCam equipped with a three-station revolver, including:

- 1 counter-clip pin

- 2 drilling pins

The change of station is ensured in 1/4″ by a Maltese cross mechanism. The locking is done by a conical finger whose axis is parallel to that of the pins, but located on a larger radius. This technique guarantees the accuracy of the positioning.

The V4 SoftCam CNC is no longer dependent on the interpretation of a language, line by line, but runs several virtual cams simultaneously. All movements made by the revolver (centering-drilling-movements of the counter-clap) can be performed simultaneously with the turning and cutting movements). This revolutionary approach allows the machine to achieve much faster production cycles than comparable CNC machines.

The SoftCam control allows very fast and very simple programming thanks to optimized pictograms and diagrams. Each operation can then be corrected individually, very easily by the operator. SoftCam can be assimilated by all operators in a few hours.

Compared to a cam machine, the SoftCam CNC control allows flexibility and productivity optimization without wasting time.

- Simple and complex parts

- Material in crowns

- Material diameter from 0.3 mm to 5 mm (maximum in mild steel)

- Turning operations with two tools

- Frontal recovery with 2 tools

- Possibility to perform drilling-de-discree and counter-drilling

- Possible operations in follower mode (mobile counter-clap depending on the material)

- Possible work without form tools

- Continuous work 24 hours

- Simple and fast gear-up thanks to SoftCam

- Easy adaptation of the production process

- Optimization of production cycles thanks to the FlexCam system, allowing better accuracy and longer tool life.

- Efficient and economical production of simple parts with short production cycles.

- Reduction in the cost of material by significant reduction in falls.

- Descolleted parts without nipple, hence the elimination of an expensive recovery.

- Since the piece is better supported, the advances for diving operations or cutting can be stronger.

- Reduction of manufacturing costs by the reduced size of crunn machines (compact design).

- Reduction of labor thanks to the feeding of machines (material loaded by crown) at longer intervals, real continuous work 24/24h. The operator has the necessary time to drive more machines.

- Production stoppages due to the load are more spaced.

Get in touch with us.

If you have any questions, or would like a quote please call 603-524-0082, or leave us a message by filling out our contact form. You can also send us and email if you prefer to info@swissettool.com.